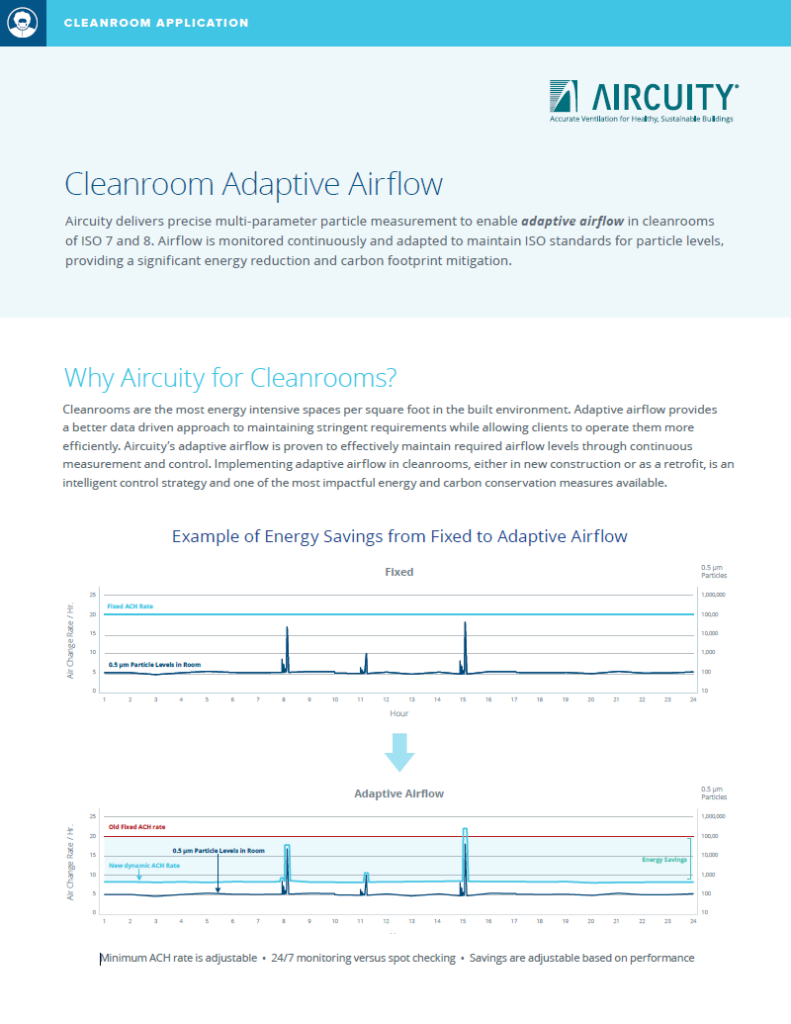

Aircuity can deliver precise and accurate demand control ventilation including 0.5 micron particle count measurements and control signals to help vary air change rates in cleanrooms of class 10,000 (ISO 7) and above. Although energy savings can be significant, the largest benefit is Aircuity’s continuous monitoring and data reporting versus the typical single, short-term measurement.